The Skinny on Pump Shear and Dicamba Drift

The last two seasons have brought headlines of farmers who faced challenges when they applied a dicamba herbicide to their field — as well as to some who did not. More often than not, inadvertent dicamba drift was publicized to be the main culprit for damaged crops and bad feelings between neighbors.

At WinField United, we heard the stories. And we have a solution to help limit dicamba drift, giving you greater peace of mind.

If you have planted or intend to plant dicamba-tolerant soybeans or cotton this year, using a superior drift reduction adjuvant (DRA) is key to keeping your dicamba applications on target. However, not all DRAs are created equal. Some can break down in the spray tank due to shear in the pump. This renders them largely ineffective.

Finding answers

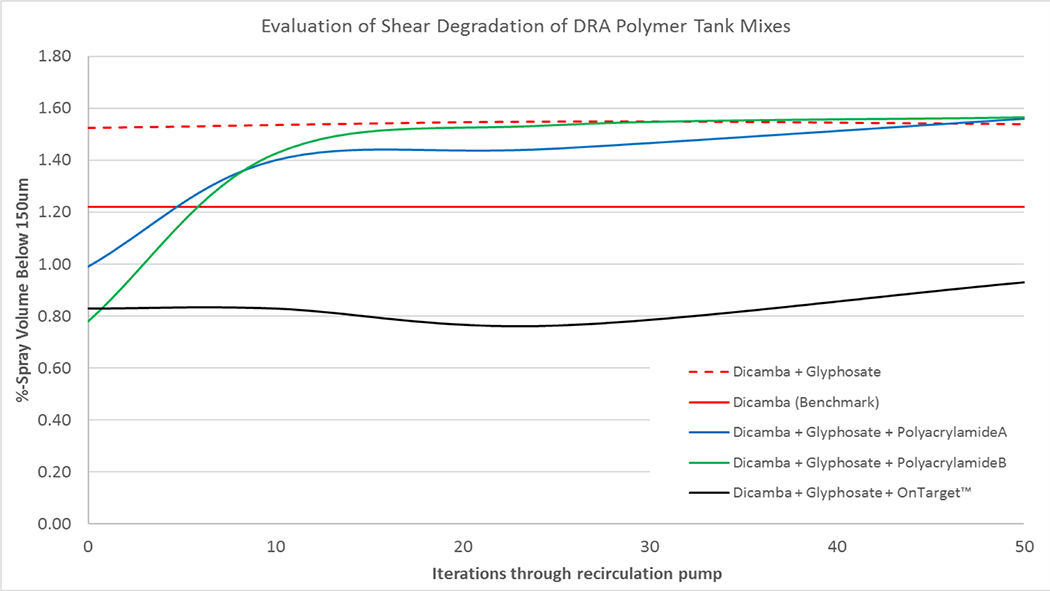

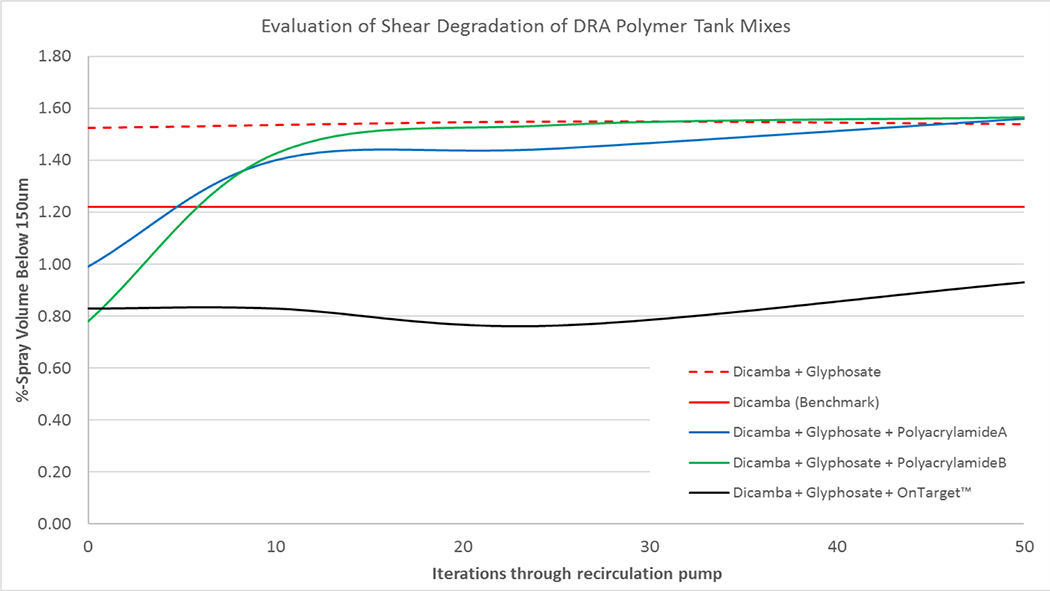

As part of our rigorous WinField® United Product Development Process, we evaluated several DRAs with new dicamba herbicide tank mixes using the WinField® United Spray Analysis System. In our lab-scale testing, some DRAs lost their ability to reduce driftable droplets due to the high shear environment of the pump simulation.1

But our testing also revealed a promising opportunity.

We found that OnTarget™ adjuvant was more resistant to shear breakdown, maintaining its drift-reduction technology, even after 50 passes through a sprayer pump simulation.

The pump shear problem

All DRAs start out by decreasing drift when mixed with dicamba. But some may not sustain that performance over time because they are subjected to shear forces in the pump, which occurs when some liquid moves faster than neighboring elements. The theory is that shear force causes the polymers in some DRAs to break apart, diminishing drift control.

OnTarget is formulated to be compatible with extra- and ultra-coarse nozzles and dicamba-based tank mixes, and its anti-foam formulation makes application convenient.

Adding OnTarget to the tank can give you more confidence about your spray outcomes. Make sure you’re getting the most out of your herbicide investment by reducing drift, enhancing droplet spreading and improving canopy penetration. Talk with your trusted local advisor about how OnTarget can work for your dicamba-tolerant crops this year.

Editor’s Note: This article was originally published in June 2018 and was updated in March 2019.

1. Bissell, D. C., Brown, D., Magidow, L. C., and Gednalske, J. V., “An Assessment of Polymeric Drift Reduction Adjuvant Performance After Prolonged Exposure to Pump Induced Shear,” Pesticide Formulation and Delivery Systems: 38th Volume, Innovative Application, Formulation, and Adjuvant Technologies, ASTM STP1610, B. K. Fritz and T. R. Butts, eds., ASTM International, West Conshohocken, PA; 2018.

Because of factors outside of WinField United's control, such as weather, applicator factors, etc., results to be obtained, including but not limited to yields, financial performance, or profits, cannot be predicted or guaranteed by WinField United. Actual results may vary.

At WinField United, we heard the stories. And we have a solution to help limit dicamba drift, giving you greater peace of mind.

If you have planted or intend to plant dicamba-tolerant soybeans or cotton this year, using a superior drift reduction adjuvant (DRA) is key to keeping your dicamba applications on target. However, not all DRAs are created equal. Some can break down in the spray tank due to shear in the pump. This renders them largely ineffective.

Finding answers

As part of our rigorous WinField® United Product Development Process, we evaluated several DRAs with new dicamba herbicide tank mixes using the WinField® United Spray Analysis System. In our lab-scale testing, some DRAs lost their ability to reduce driftable droplets due to the high shear environment of the pump simulation.1

But our testing also revealed a promising opportunity.

We found that OnTarget™ adjuvant was more resistant to shear breakdown, maintaining its drift-reduction technology, even after 50 passes through a sprayer pump simulation.

The pump shear problem

All DRAs start out by decreasing drift when mixed with dicamba. But some may not sustain that performance over time because they are subjected to shear forces in the pump, which occurs when some liquid moves faster than neighboring elements. The theory is that shear force causes the polymers in some DRAs to break apart, diminishing drift control.

OnTarget is formulated to be compatible with extra- and ultra-coarse nozzles and dicamba-based tank mixes, and its anti-foam formulation makes application convenient.

Adding OnTarget to the tank can give you more confidence about your spray outcomes. Make sure you’re getting the most out of your herbicide investment by reducing drift, enhancing droplet spreading and improving canopy penetration. Talk with your trusted local advisor about how OnTarget can work for your dicamba-tolerant crops this year.

Editor’s Note: This article was originally published in June 2018 and was updated in March 2019.

1. Bissell, D. C., Brown, D., Magidow, L. C., and Gednalske, J. V., “An Assessment of Polymeric Drift Reduction Adjuvant Performance After Prolonged Exposure to Pump Induced Shear,” Pesticide Formulation and Delivery Systems: 38th Volume, Innovative Application, Formulation, and Adjuvant Technologies, ASTM STP1610, B. K. Fritz and T. R. Butts, eds., ASTM International, West Conshohocken, PA; 2018.

Because of factors outside of WinField United's control, such as weather, applicator factors, etc., results to be obtained, including but not limited to yields, financial performance, or profits, cannot be predicted or guaranteed by WinField United. Actual results may vary.