What Can a Digital Twin Do for You?

Anything that’s mechanical breaks down at some point. Take your vehicle, for example. Doesn’t it seem like when one thing breaks, a chain reaction of service appointments follow? It’s as if the bearings, bushings and spindles that comprise the machine are part of a greater living organism.

Leading-edge industrial companies have begun exploring ways to datafy and predict upcoming maintenance on their machines by building virtual look-alikes. These look-alikes allow technicians to peer inside a system using sensors, machine inputs and machine outputs, as well as add the predictability of downtime, schedule replacement parts and achieve greater uptime for the machine.

Could we use these same techniques in production agriculture?

What is a Digital Twin?

In short, a digital twin is a dynamic software model of a physical thing or system. Its purpose is to analyze and simulate real-world conditions, anticipate response to changes and improve operations to add more value for the end-user. A digital twin uses sensors in the physical world along with scientific data or set input parameters to model a specific scenario. It is constantly evolving and learning with the ability to update itself based on input from multiple sources. In essence, a digital twin can be manipulated to see how the real version might respond under a particular set of circumstances.

Farming a Digital Field

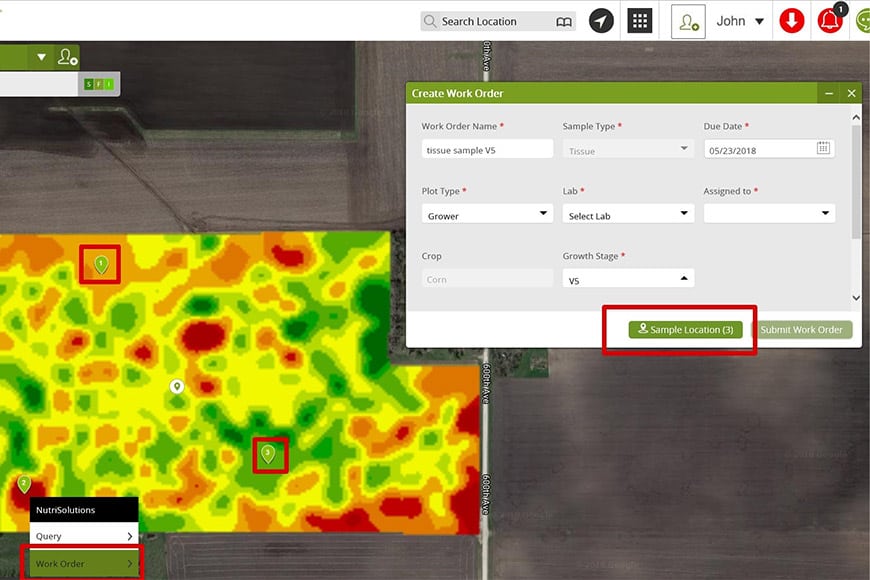

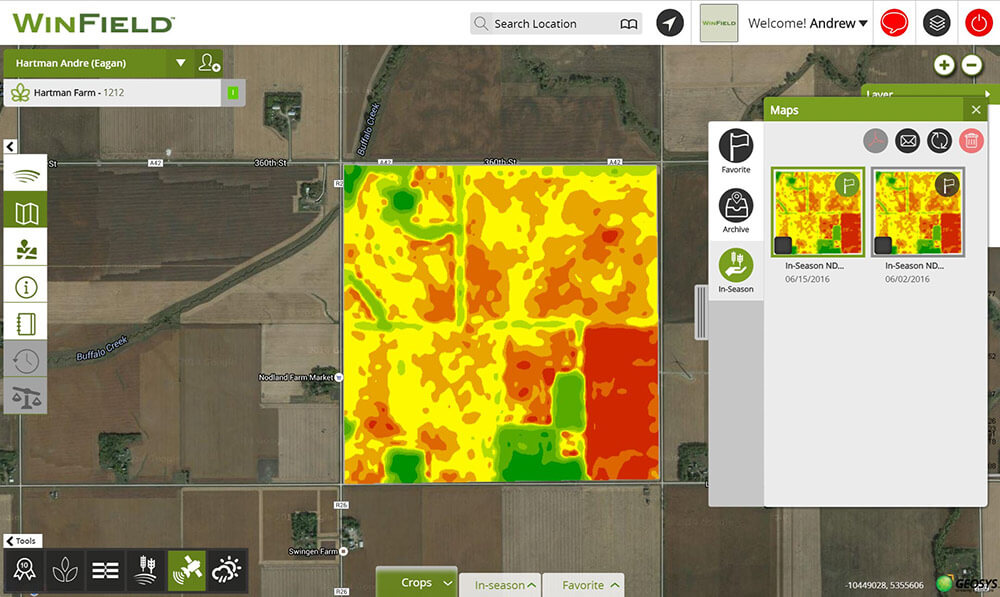

While the term digital twin may be new, the concept is not. Lots of companies are using modeling and algorithms to anticipate or solve problems for customers before they happen. In the ag world, there are a number of different modeling tools out there that are designed to increase productivity while helping to manage risk.

Crop modeling is just one example of using a digital twin to understand how environmental and management practices can affect yield potential. If you have enough information to feed into the model, you can make predictions on any number of parameters related to crop production. The more things on the farm you can quantify, the more opportunities you have to make real-time decisions to improve profitability. Want to know how much nitrogen you need to supplement in order to meet your yield goals? Just run the model. Wondering how to irrigate more efficiently? A model can tell you.

The Human Element

Modeling is a great tool to help manage risk, as it allows you to invest little time, energy and money upfront to better understand how your management decisions could affect profitability. The caveat is that you need to understand what parameters went into creating the model and understand its limits. A model is only as good as the data that went into creating it, and no model can substitute for the knowledge and experiences you’ve gained on the farm. Rely on your trusted agronomic advisors to help make sense of what digital twins are telling you.

Leading-edge industrial companies have begun exploring ways to datafy and predict upcoming maintenance on their machines by building virtual look-alikes. These look-alikes allow technicians to peer inside a system using sensors, machine inputs and machine outputs, as well as add the predictability of downtime, schedule replacement parts and achieve greater uptime for the machine.

Could we use these same techniques in production agriculture?

What is a Digital Twin?

In short, a digital twin is a dynamic software model of a physical thing or system. Its purpose is to analyze and simulate real-world conditions, anticipate response to changes and improve operations to add more value for the end-user. A digital twin uses sensors in the physical world along with scientific data or set input parameters to model a specific scenario. It is constantly evolving and learning with the ability to update itself based on input from multiple sources. In essence, a digital twin can be manipulated to see how the real version might respond under a particular set of circumstances.

Farming a Digital Field

While the term digital twin may be new, the concept is not. Lots of companies are using modeling and algorithms to anticipate or solve problems for customers before they happen. In the ag world, there are a number of different modeling tools out there that are designed to increase productivity while helping to manage risk.

Crop modeling is just one example of using a digital twin to understand how environmental and management practices can affect yield potential. If you have enough information to feed into the model, you can make predictions on any number of parameters related to crop production. The more things on the farm you can quantify, the more opportunities you have to make real-time decisions to improve profitability. Want to know how much nitrogen you need to supplement in order to meet your yield goals? Just run the model. Wondering how to irrigate more efficiently? A model can tell you.

The Human Element

Modeling is a great tool to help manage risk, as it allows you to invest little time, energy and money upfront to better understand how your management decisions could affect profitability. The caveat is that you need to understand what parameters went into creating the model and understand its limits. A model is only as good as the data that went into creating it, and no model can substitute for the knowledge and experiences you’ve gained on the farm. Rely on your trusted agronomic advisors to help make sense of what digital twins are telling you.