5 Ways to Find Success With Fungicides

It’s time to bust the myth once and for all that fungicides aren’t worth investing in. Research has continually shown yield advantages when a fungicide application is made. In fact, our Answer Plot® trials have consistently shown an average of more than 10 bushel per acre increases in corn yields when a fungicide is applied.

The question is: How can you tweak your strategy to get the greatest ROI potential? Here are some ideas.

1. Choose the Right Products

Selecting the right fungicide products may seem like a no-brainer but it’s easier said than done. It also has a major impact on fungicide efficacy. When making the decision, there are many factors to consider:

-

In corn, a hybrid’s response-to fungicide (RTF) score is based on randomized, replicated research trials conducted at WinField® United Answer Plot locations where more than 200 hybrids are tested each year. Hybrids with high to medium RTF scores respond greatly to a fungicide application, which means investing in a premium product will likely pay off on those acres. Those with low RTF scores may result in a smaller yield advantage, so a lower cost option may be best for those fields.

-

In soybeans, a variety’s disease tolerance is an important factor. Soybean varieties more susceptible to disease may be the best candidates for premium fungicides to maximize control and, in turn, optimize yield potential.

-

Weather is also important as it can be an indication of expected disease and stress prevalence. Yield potential changes with any major weather patterns, and fungicides can have an impact in both wet and dry scenarios. Wet conditions can lead to disease, warranting a fungicide application for disease control. Crops experiencing dry conditions would likely benefit from the strobilurin component of fungicides that provides stress mitigation and plant physiology benefits under stressful conditions.

-

Disease type and prevalence is another key consideration. Not all products will work on all diseases. Anticipate the type of diseases common to your geography or weather conditions and choose the right product to address that disease spectrum. However, low disease pressure doesn’t always mean there’s no need for fungicides. Answer Plot data indicates fungicides still pay off when disease is relatively low in the field, thanks to the plant health benefits of strobilurin products.

2. Determine Optimal Timing

The most traditional time to apply a fungicide is around VT or tassel. At that point, the corn still has about 55-60 days before the grain matures, so the main management goal is to protect the plant from disease to maximize grain fill. Based on Answer Plot testing, this is the best time to make an application in corn if you are planning on a one-time application strategy this season.

Backing up a couple growth stages, V10 through V14 is another great opportunity to begin applying a fungicide. This is when the corn plant is determining the potential ear length and how many kernels it will contain. Stressors like heat, drought and disease during this stage could impact those characteristics and cause a loss in yield potential. Taking advantage of the plant health and physiological benefits of fungicides could help maximize yield potential during this growth stage.

When making timing decisions, it’s also important to consider a product’s residual activity. With some older products, we typically estimate a 21-day period of residual activity and target those for tassel time applications so they last as far into grain fill as possible. Newer products with next-generation triazoles or SDHI active ingredients and a longer residual activity period may be a better fit for pre-tassel applications with ground equipment.

In soybeans, optimal timing is around R3, when the pods are just starting to form. Depending on the soybean maturity, however, R3 can last several weeks. Even if a fungicide application is made at beginning R3, growers and retail agronomists should begin scouting two-three weeks later to see if another fungicide and/or insecticide application is warranted.

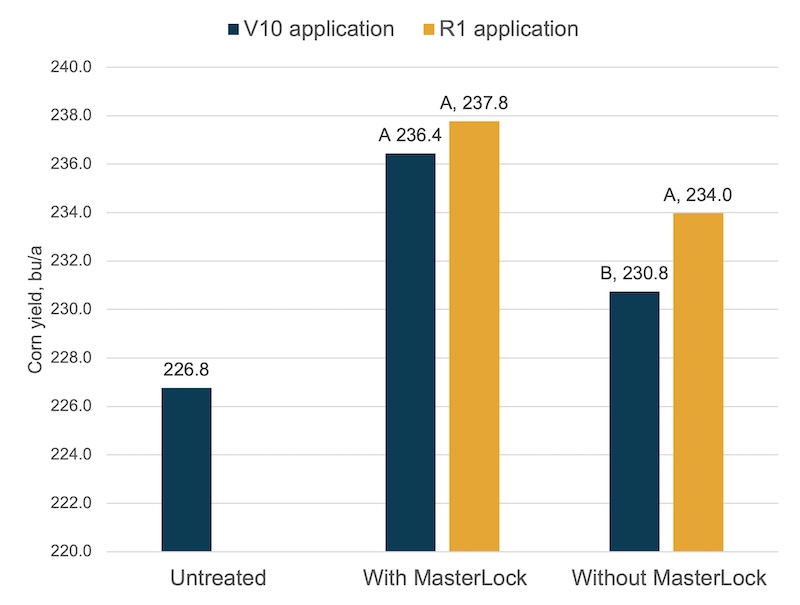

Fungicide Application Timing Results

3. Prioritize Applications

While it would be great to apply fungicides to every acre exactly when they would respond most, it’s not logistically possible for every field to be sprayed at the most optimal time. Maybe it’s due to weather, to a backlog in available applicators or to product shortages. Whatever the reason, it’s important to prioritize applications to make your fungicide investment work the hardest.

Once again, RTF scores are valuable in these scenarios. Prioritize the high- and moderate-RTF hybrids since you know those are likely to show the greatest return, but don’t neglect your low-RTF hybrids. There’s a misconception that low-RTF hybrids don’t benefit from a fungicide but, while it’s true they’re not going to respond quite as well, given the right weather conditions and right disease, they can still show positive impacts from a fungicide. So, while your high- and medium-RTF hybrids are being sprayed, take time to scout those fields with low-RTF products to see what and how much disease there is and make your decision from there.

4. Ensure Sufficient Coverage

To maximize the efficacy of a fungicide product, sufficient coverage is a must. One of the most influential factors that impacts coverage is the amount of water that’s applied. While an airplane is going to apply around 2 gallons per acre, a ground sprayer will apply up to 20 gallons per acre. Naturally, the higher rate of the ground sprayer will lead to more coverage on the plant.

With an aerial application especially, when coverage is already limited by the amount of water being used, a product like MasterLock® adjuvant can help keep that small, valuable solution volume from drifting off course to help ensure more product makes it to the target. In fact, data shows a 5.7-bushel per acre average yield increase in corn when MasterLock adjuvant is added to the spray tank along with a fungicide, compared to using a fungicide alone.1

5. Get More from Your Fungicide Pass

Since you’re already making a trip across the field to make your fungicide application, add another plant health boost to the tank with micronutrients. To determine which to apply, take a tissue test three to five days before you plan to spray so you have time to get results back from SureTech® Laboratories and determine the specific needs of each field. If that’s not feasible, the next best option is to take a look at our tissue test data and see which nutrients are most in need in your area and similar conditions. Typically, our most popular micronutrient products applied at fungicide timing are MAX-IN® Ultra ZMB® and MAX-IN Boron. Both high-quality micronutrients include CornSorb® technology, which helps increase nutrient availability and uptake by plants.

Learn more about how to make the most of your fungicide application or contact your locally owned and operated WinField United retailer to determine specific fungicide strategies for your fields.

1WinField United. 14 studies, eight states, all fungicides. 2012–2017.

All photos are either the property of WinField United or used with permission.

© 2025 WinField United. Important: Before use always read and follow label instructions. Crop performance is dependent on several factors many of which are beyond the control of WinField United, including without limitation, soil type, pest pressures, agronomic practices and weather conditions. Growers are encouraged to consider data from multiple locations, over multiple years and to be mindful of how such agronomic conditions could impact results. Answer Plot, CornSorb, MasterLock, MAX-IN, SureTech and WinField are trademarks of WinField United. All other trademarks are the property of their respective owners.